Logistics Automation

Laser sensors act on the sorting, picking, transportation, collision avoidance, etc. of warehousing logistics through measurement technology, providing its efficiency, speed and reliability, optimizing the logistics chain, in industrial vehicles, building security, ports, cranes, retail and distribution centers and transportation. field plays an important role.

Stacker Positioning

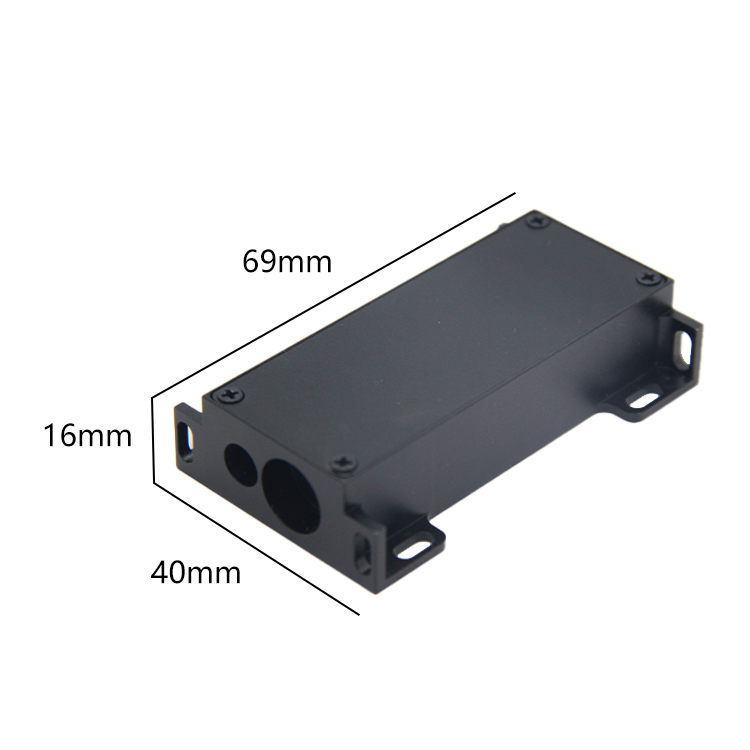

In the logistics storage center, the stacker is an indispensable part. In order to ensure accurate, reliable and high-speed positioning, a reliable positioning system is required. With its compact design, high-speed operating speed and high precision and many other technical advantages, laser ranging sensors have become the preferred solution for logistics positioning systems. The laser ranging sensor is installed in the direction of the horizontal roadway of the stacker, and is brought to the specified position through continuous measurement; or installed in the vertical direction to monitor the height of the pallet stacking, precise positioning, improve storage efficiency, and realize management automation.c

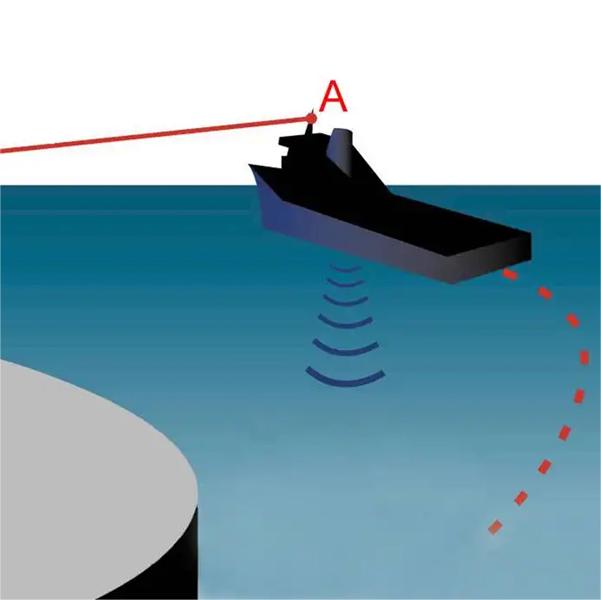

Vessel Monitoring

Seakeda smart distance sensor solutions monitor ships in dock areas. The laser rangeing sensor can reliably detect the container ship when it is berthing at the dock, and transmit its current position and speed to the portable terminal device and display it in real time, so as to realize fast and safe ship doc

Forklift Collision Avoidance

Seakeda laser ranging sensors are compact, capable and easy to install and integrate into AGV vehicles, forklifts, indoor delivery robots and other equipment. Seakeda laser ranging sensors are often used in industrial sites for obstacle avoidance, automatic and accurate ranging, avoiding obstacles in the process of operation. Use the mm precision laser distance sensor, create accurate ranging system, make its can monitor and safety distance between forklifts, forklift and forklift truck. By accurate ranging early warning, forklift accidents can be effectively prevented. Therefore, the laser ranging module is installed on the forklift to realize the integration of forklift anti-collision system and ensure the safety of the forklift.

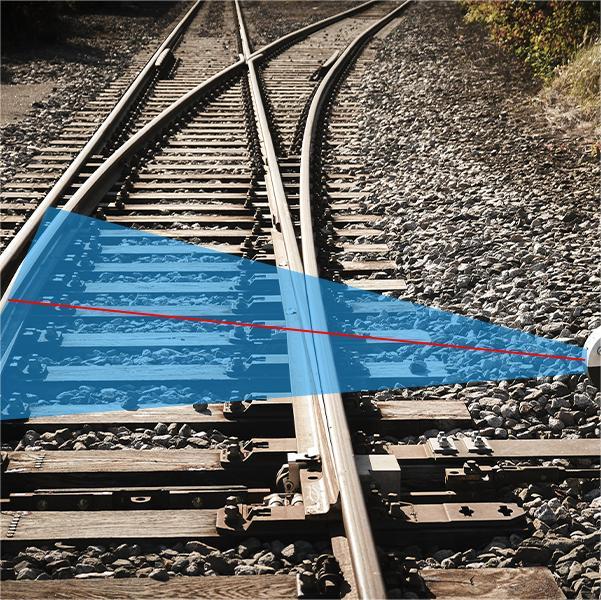

Track Deformation Monitoring

With the development of railways, more and more attention has been paid to the safety of rail traffic. Track deformation is one of the reasons for traffic accidents, so a monitoring system is needed to assist early warning. Laser ranging sensors can monitor track deformation and displacement changes through real-time ranging, real-time monitoring, and early warning, so that railway personnel can perform maintenance and avoid traffic accidents.

Logistics Volume Measurement

A conveyor belt is used to transport objects from one end to the other. For many industries, it is vital to measure the volume of objects on the conveyor belt. Laser distance sensors use a laser beam to calculate the distance between the sensor and an object. By using multiple sensors placed along the conveyor belt, the system can accurately measure the volume of objects passing through it. They can measure distance with high accuracy, can operate at high speeds, making them ideal for use in busy environments such as factories.

The volume measurement of objects on a conveyor belt has many applications. For example, it can be used to control the amount of materials being transported or to monitor the production process. In some industries, the accuracy of the measurement is crucial, and any errors can lead to losses or even danger. This is why laser distance sensors so important.

Furthermore, using laser distance sensors can bring many benefits to the production process. By providing accurate and real-time data, the system can help to prevent waste and optimize the use of resources. Additionally, automated volume measurement can reduce manual work, thus improving the efficiency of the production process.

Laser distance sensors have become an indispensable tool in measuring the volume of objects on a conveyor belt. Their high accuracy, speed, and reliability make them ideal for use in various industries. With the growing demand for automation and real-time data in production processes, laser distance sensors will undoubtedly play an increasingly important role in the future.