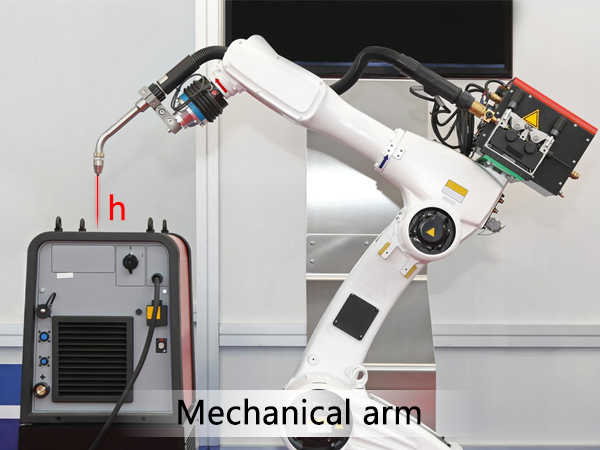

Distance Measurement Sensors by Robotic Mechanical Arm

Distance measurement sensors are crucial for robotic mechanical arms to interact accurately and safely with their environment. These distance measurement laser sensors help in tasks such as object detection, obstacle avoidance, and precise positioning. Here are some common types of distance measurement sensors used in robotic mechanical arms:

1. Industrial Laser Distance Sensors (LIDAR):

- Working Principle: Use laser light to measure the distance to an object by calculating the time it takes for the light to reflect back.

- Advantages: High accuracy 1mm, long range, and can be integrated to smart devices.

- Disadvantages: More expensive and may require more processing power.

2. Time-of-Flight (ToF) Rangefinder Sensor:

- Working Principle: Measure the time it takes for infrared light to travel to an object and back to the laser ranging sensor.

- Advantages: Provide super long distance measure for the outdoor scene, useful for military and object recognition.

- Disadvantages: Can be affected by ambient light, and the resolution may be lower than other measure distance sensor methods.

3. Infrared (IR) Rangefinder Module Sensors:

- Working Principle: Use infrared light to detect objects and measure distance based on the reflection time.

- Advantages: Compact, low power consumption, and can be used in a wide range of applications.

- Disadvantages: Limited range, sensitive to ambient light, and may not work well with dark or reflective surfaces.

Integration and Applications

- Object Detection and Recognition: Used to identify and locate objects for picking, placing, and manipulation.

- Obstacle Avoidance: Helps the robotic arm avoid collisions with objects in its path.

- Precision Positioning: Ensures that the arm can move to and from specific points with high accuracy.

- Environment Mapping: Creates a 3D map of the surroundings for navigation and planning.

Considerations for Selection

- Range and Accuracy: Choose a distance measurement laser sensor that meets the required range and precision for the task.

- Environmental Factors: Consider the operating environment, including lighting, temperature, and the presence of dust or other contaminants.

- Cost and Complexity: Balance the cost and complexity of the industrial laser distance sensor with the requirements of the application.

- Integration and Compatibility: Ensure that the rangefinder sensor can be easily integrated into the existing robotic system and that it is compatible with the control software.

By carefully selecting and integrating the appropriate rangefinder module and distance measurement sensors, robotic mechanical arms can perform a wide range of tasks with high accuracy and reliability.

Email: sales@seakeda.com

WeChat: 86-18302879423

Post time: Feb-20-2025