Products

5m Laser Distance Meter Sensor Arduino

Product Introduction

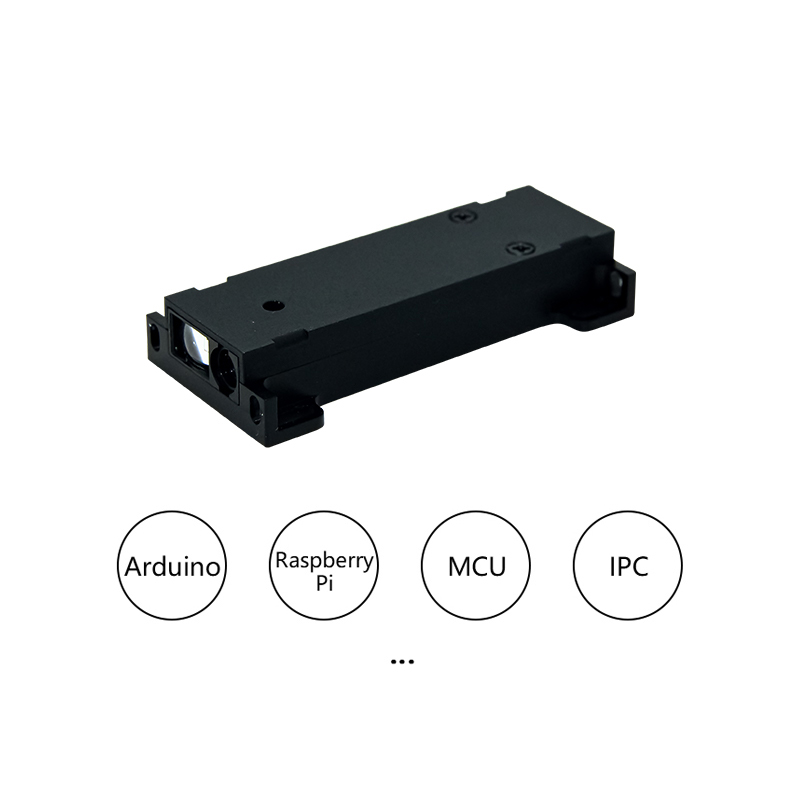

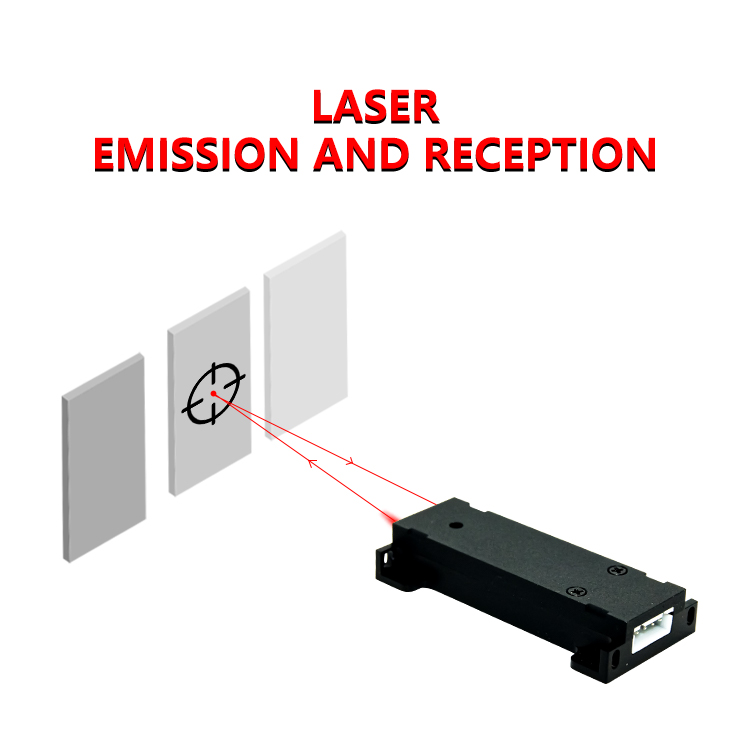

5m invisible light laser distance measuring sensor is a device that uses laser technology for ranging, by measuring the distance between the object and the sensor, and providing high-precision ranging results. It adopts Class 1 invisible safety laser, and the TTL-USB, RS232/RS485 interface can be connected to a computer to output measurement data. Widely used in medical, industrial automation, robotics, indoor positioning equipment and other fields, it can realize accurate distance measurement and positioning functions.

Features

1. Wide measurement range and strong accuracy

2. Fast response speed, high measurement accuracy and large range

3. The power is stable, the power consumption is extremely small, and the working time is long.

4. Small size and light weight, easy to integrate into small devices

Parameters

| Model | S91-5 |

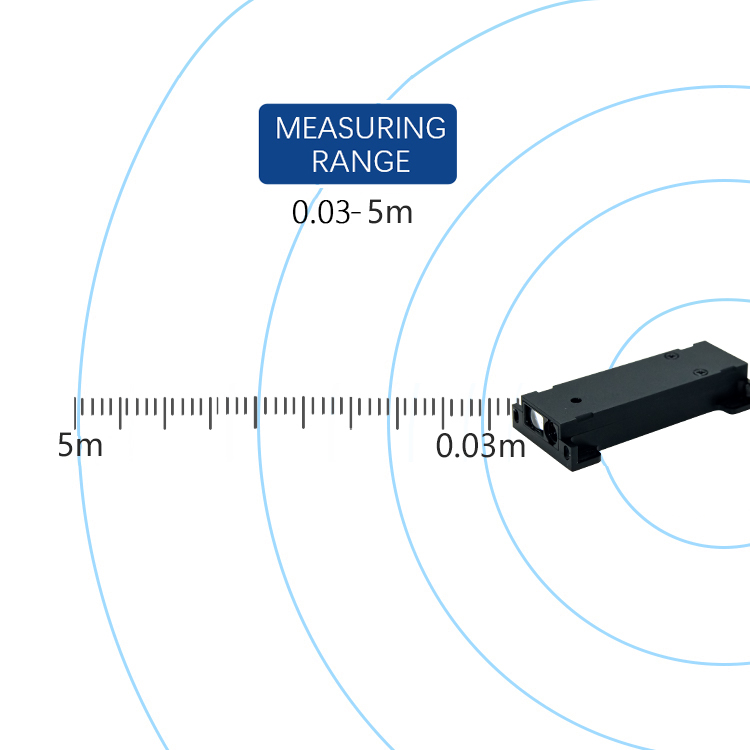

| Measuring Range | 0.03~5m |

| Measuring Accuracy | ±1mm |

| Laser Grade | Class 1 |

| Laser Type | 620~690nm,<0.4mW |

| Working Voltage | 6~32V |

| Measuring Time | 0.4~4s |

| Frequency | 3Hz |

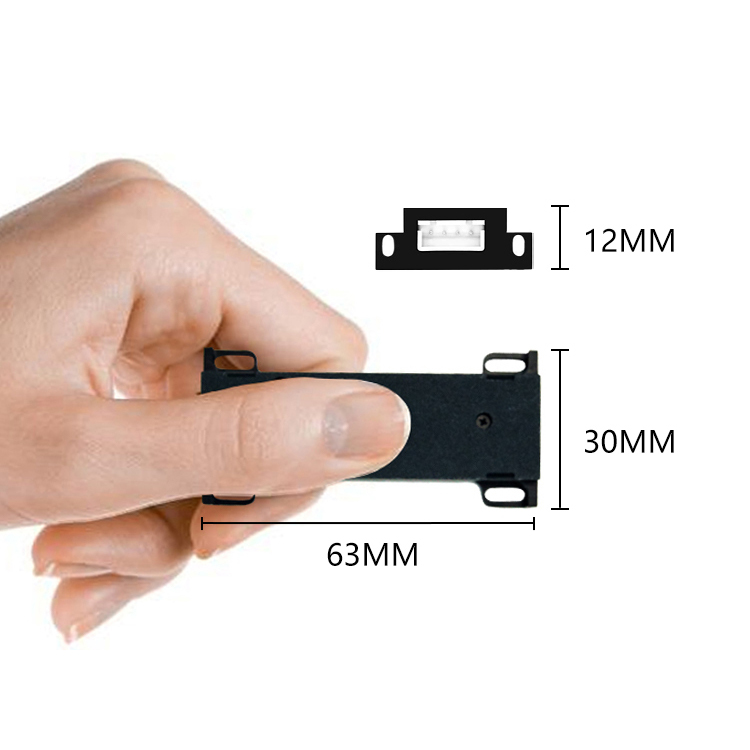

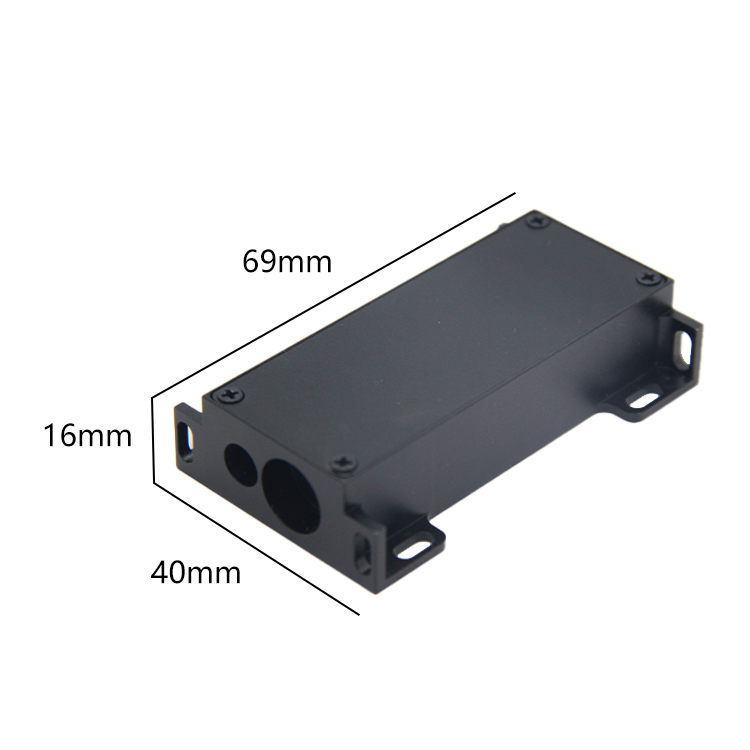

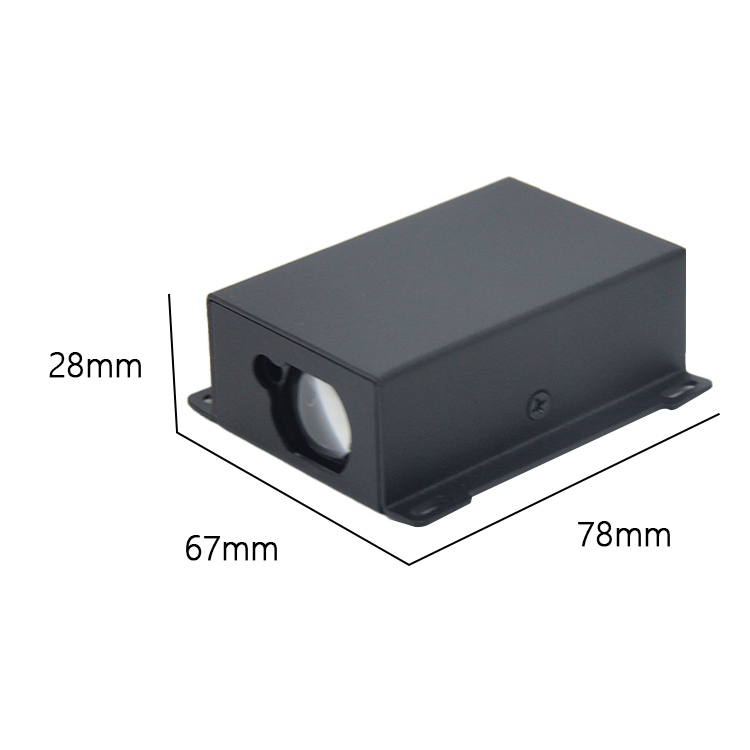

| Size | 63*30*12mm |

| Weight | 20.5g |

| Communication Mode | Serial Communication, UART |

| Interface | RS485(TTL/USB/RS232/ Bluetooth can be customized) |

| Working Temperature | 0~40℃(Wide temperature -10 ℃ ~ 50 ℃ can be customized) |

| Storage Temperature | -25℃-~60℃ |

Application

fields of laser range sensor:

1. Bridge static deflection monitoring system

2. Tunnel overall deformation monitoring system, tunnel key point deformation monitoring system

3. Liquid level, material level, material level monitoring system

4. Balance Monitoring System

5. Positioning and alarm system in transportation, hoisting and other industries

6. Thickness and dimension monitoring system

7. Mine elevator, large hydraulic piston height monitoring, positioning monitoring system

8. Monitoring system for dry beach, tailings, etc.

FAQ

1. What are the advantages of laser distance measurement sensors?

The equipment is small in size and high in accuracy, has a wide range of applications, and is cost-effective and economical.

2. What issues should be paid attention to when choosing a laser ranging sensor?

First of all, it is necessary to pay attention to the structure and material of the measuring object. The uneven phenomenon of the measuring object and the use of reflective materials often directly affect the use effect of the laser ranging sensor. Secondly, it is necessary to pay attention to the parameter indicators of the sensor, because the accuracy of the parameters also directly affects the accuracy of the measurement.

3. What should be paid attention to when using the laser measuring sensor?

Pay attention to check before use and avoid using faulty instruments, do not aim at strong light sources or reflective surfaces, avoid shooting at the eyes, and avoid measuring unsuitable surfaces.