Products

20HZ Industrial Laser Measurement Distance Sensor Manufacturer

Product Introduction

The laser non contact distance measurement sensor uses the laser phase method to measure, and can measure the distance to the surface of the object or the surface of the reflective target without contact. It is suitable for industrial applications, especially for high-precision, non-direct contact applications, such as crane positioning and metallurgical production line control.

Seakeda's Industrial laser distance sensors can support data communication and secondary development. It always supports data communication via Bluetooth, RS232, RS485, USB, and so on. and also can be applied to Arduino, Raspberry Pi, UDOO, MCU, PLC, and so on. Because our Industrial laser distance sensor has the huge function, many industrial projects use our industrial sensors.

Overall, the 20HZ Industrial Laser Distance Sensor offers high speed, high accuracy distance measurement capabilities, making it an essential tool for a wide range of industrial applications.

Features

1.Laser class 2, safe laser

2.The laser emission power is stable and can achieve millimeter-level measurement accuracy

3.The red laser is easy to aim at the measured target, which is convenient for installation and debugging

4.The protection level is IP54, which can be used in most harsh industrial sites

5.Equipped with professional testing software

6.Power supply 5-32V DC wide voltage

Parameters

| Model | M91-60 | Frequency | 3Hz |

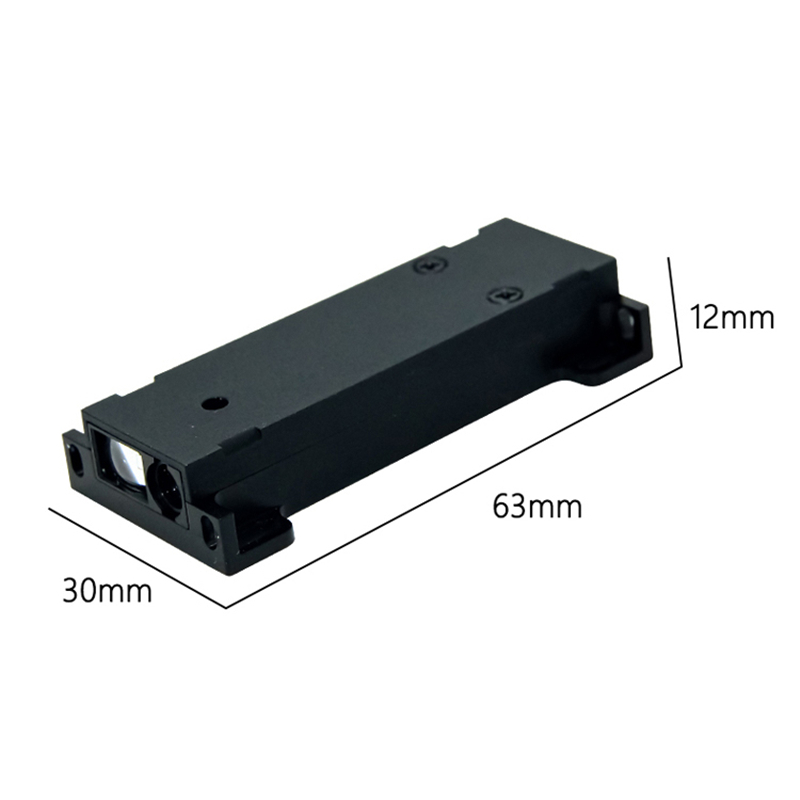

| Measuring Range | 0.03~60m | Size | 69*40*16mm |

| Measuring Accuracy | ±1mm | Weight | 40g |

| Laser Grade | Class 2 | Communication Mode | Serial Communication, UART |

| Laser Type | 620~690nm,<1mW | Interface | RS232(TTL/USB/RS485/ Bluetooth can be customized) |

| Working Voltage | 5~32V | Working Temperature | 0~40℃(Wide temperature -10 ℃ ~ 50 ℃ can be customized) |

| Measuring Time | 0.4~4s | Storage Temperature | -25℃-~60℃ |

Note:

1. Under bad measure condition, like environment with strong light or the diffuse reflectance of measuring point over-high or low, the accuracy would have bigger amount of error: ±1 mm± 50PPM.

2. Under strong light or bad diffuse reflectance of target, please use a reflection board

3. Operating temperature -10 ℃~50 ℃ can be customized

Application

Laser measurement sensor has a wide range of industrial applications:

1. Measurement of objects that are not suitable for close proximity, and the laser distance sensor can non-contact measurement of distant and target color changes.

2. In the field of automation, the problem of long distance measurement and inspection is solved in the method of automatic detection and control. It can be used to measure the material level, measure the object distance and object height on the conveyor belt, etc.

3. Vehicle speed, safe distance measurement, traffic statistics.

4. the bridge static deflection online monitoring system, the tunnel overall deformation online monitoring system, the tunnel key point deformation online monitoring system and the mine elevator, the large hydraulic piston height monitoring.

5. Height limit measurement, building limit measurement; monitoring of the safe docking position of ships, container positioning.

FAQ

1.Laser range sensor does not appear laser spot?

Check whether the positive and negative poles of the power cord are connected correctly, and then check the signal output, input, and common lines. The main reason is that the negative and common lines of the power supply are easy to be confused. When these lines are checked correctly, this problem will be solved.

2.The laser distance meter sensor and the computer cannot be connected?

Check whether the laser ranging software is installed on the computer. If there is and the installation is correct, please check whether your wiring is correct.

3.What are the good working conditions for laser range measurement?

Good measurement conditions: the reflective surface target has good reflectivity, 70% is the best (diffuse reflection instead of direct reflection); ambient brightness is low, no strong light interference; operating temperature is within the allowable range.